Everything you need, in one place.

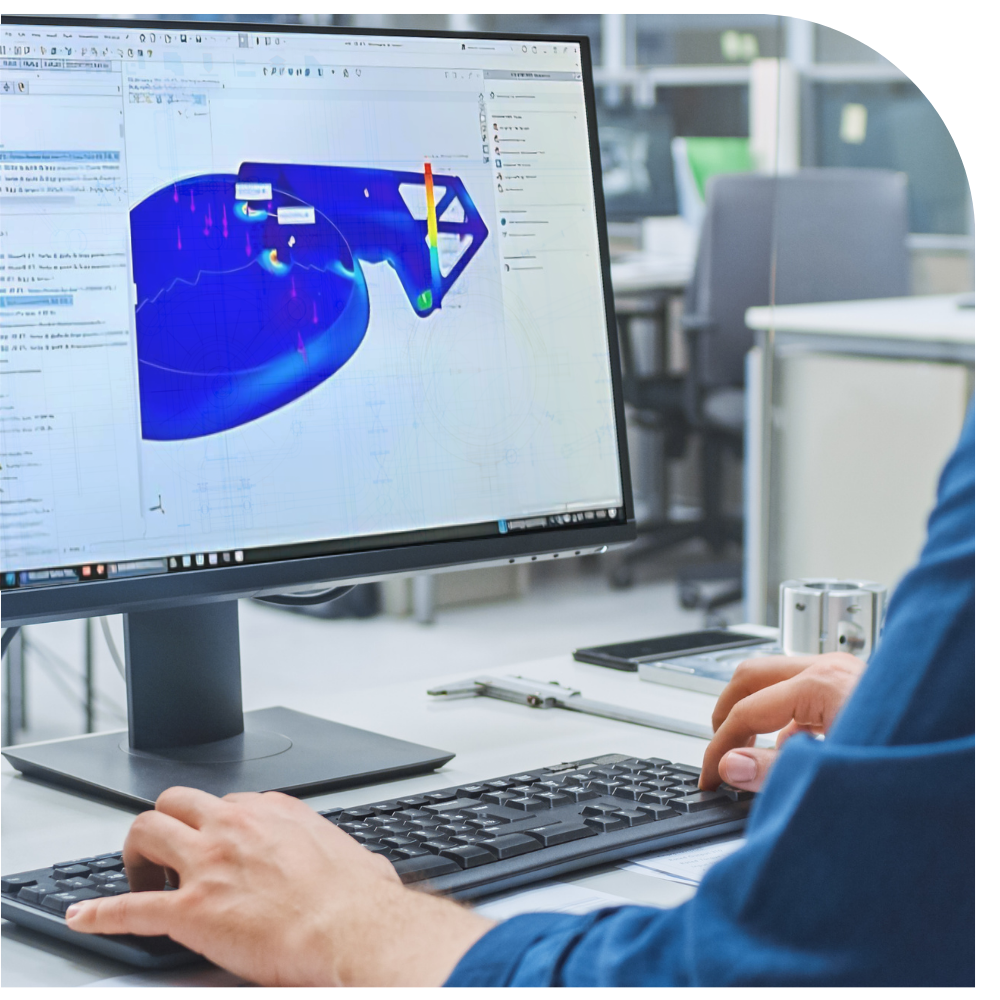

ENGINEERING & DESIGN 01

Our company places the utmost importance on meeting the unique needs and expectations of our customers, in the food industry. We work directly with our customers to understand their production processes, capacity and quality standards in order to design and develop equipment adapted to their requirements.

Our engineering team then starts the design phase, using the latest software to create detailed models of the proposed solution.

Our commitment to excellence and client satisfaction drives us to create tailored solutions that go above and beyond customer expectations, as we recognize the vital role that hygiene and quality play in the food industry.

PRODUCTION 02

After the design phase is finalized, we transition into the development stage, where innovation and precision take center stage. Utilizing state-off-the-art techniques and materials, our skilled manufacturing team goes to work, crafting the equipment that will power your vision.

With over two decades of experience, our manufacturing team ensures that your ideas are not only brought to life but are executed with utmost fidelity to the original design.

We understand that the success of any project relies on the quality of its implementation, and we take great pride in delivering results that exceed expectations.

AUTOMATION & SOFTWARE 03

The development and implementation of automation, software, and electrification are en trusted to the proficient hands of our dedicated Fazendas® automation and electrification department. This specialized team operates in full alignment with the latest edition of the Good Automated Manufacturing Practice (GAMP) guidelines, ensuring that our processes meet the highest industry standards for reliability and quality.

Additionally, our Supervisory Control and Data Acquisition (SCADA) systems, responsible for overseeing and controlling operations, are crafted in strict compliance with the stringent regulations outlined in 21 CFR Part 11.

- Solution tailored to the user experience

- User-friendly control/visualization

- Recipes

- Preventive maintenance

- Reporting

- Event tracking

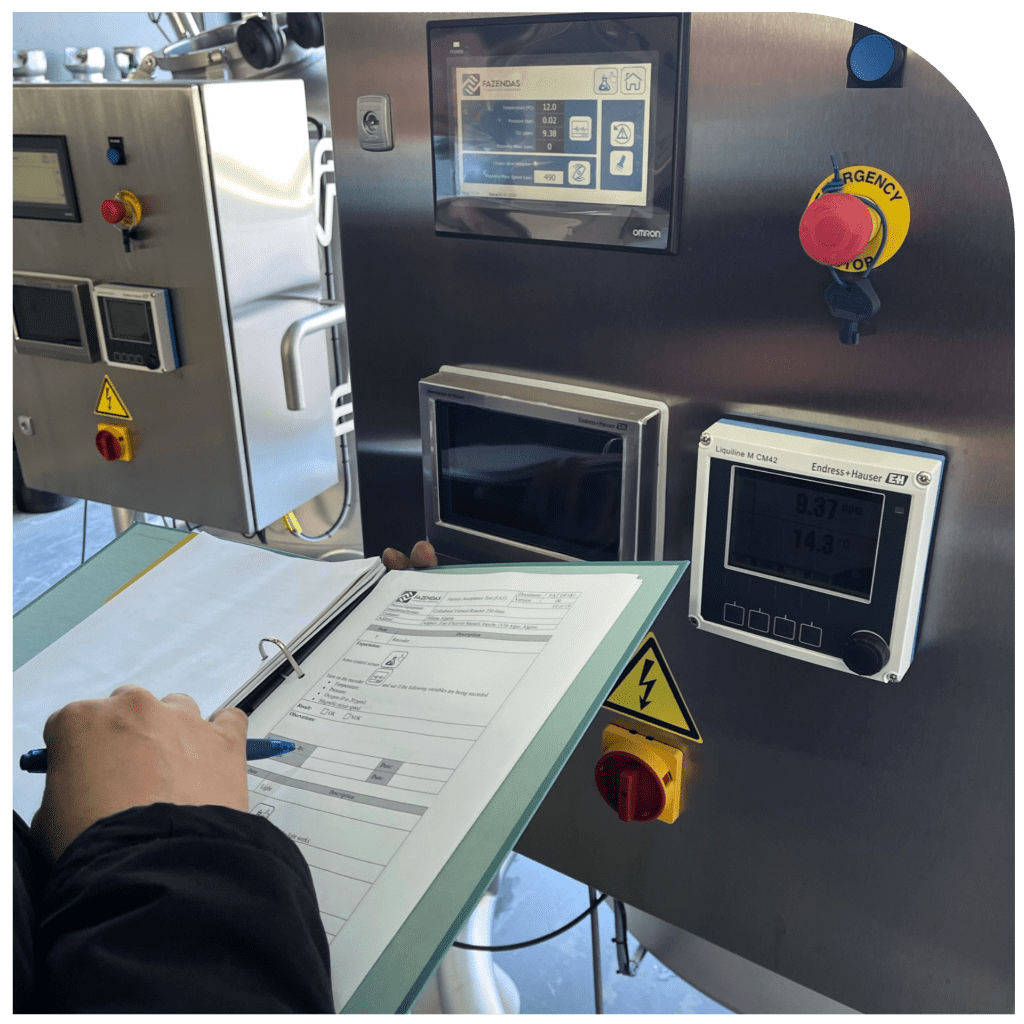

FACTORY ACCEPTANCE TEST | FAT 04

Once the development process is complete, we conduct the Factory Acceptance Test (FAT), where we rigorously test the equipment to ensure it meets our reliability, efficiency and performance standards.

From stress tests to simulated real-world conditions, we ensure the equipment manufactured is up to its mission.

Therefore, our customers can be confident that when their equipment arrives it will be ready for use.

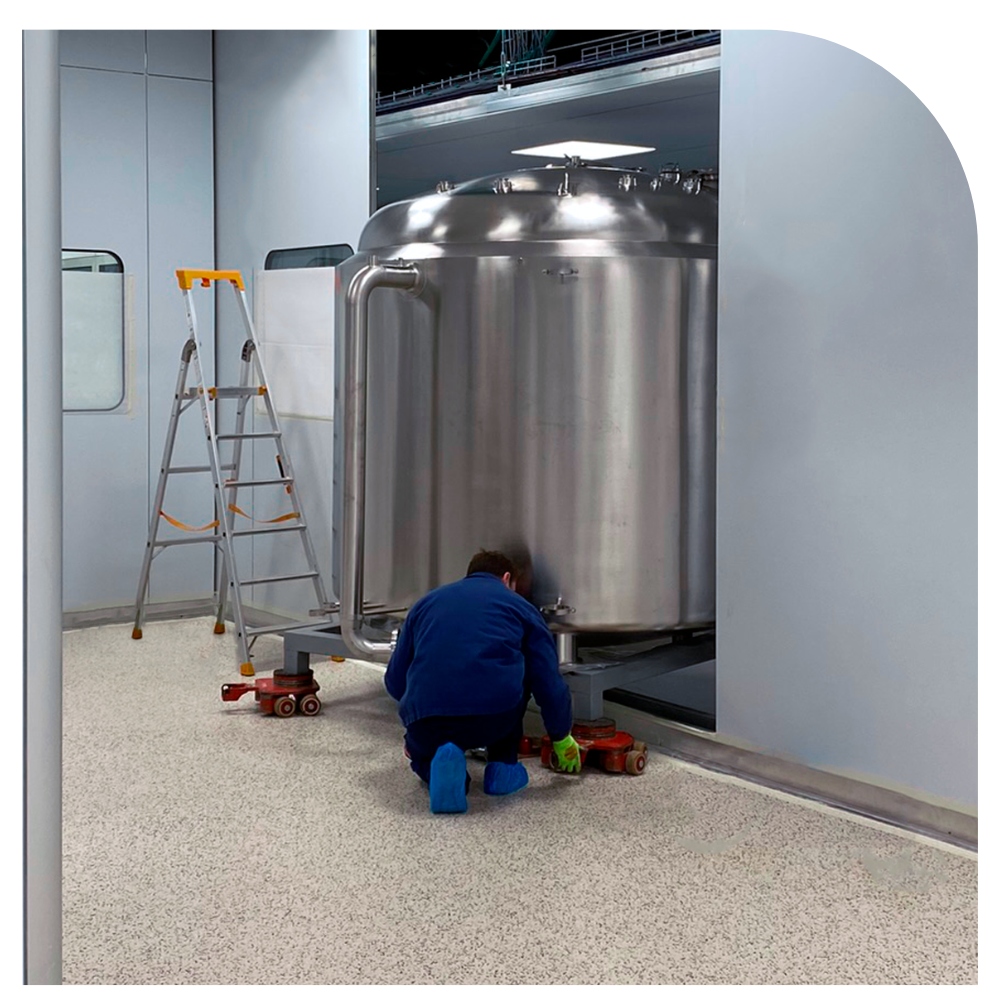

ON-SITE INSTALLATION 05

Following the development phase, we proceed to the crucial stage of installation and commissioning.

During the installation phase, our dedicated technicians embark on-site, where they meticulously assemble and install all the components with utmost care. Every component is handled with precision and attention to detail to guarantee that it is correctly positioned and securely mounted. Safety is our utmost concern, and our technicians ensure that every installation adheres to the highest safety standards to safeguard both personnel and equipment.

The commissioning process that follows is equally significant. Our skilled team ensures that every component operates seamlessly and in harmony with the entire system. This entails rigorous testing and conducting comprehensive checks and verifications to ensure that the system is operational and performing at peak efficiency.

VALIDATION AND TRAINING 06

We also offer validation and training services to ensure that our solutions meet industry standards and regulations and that the customer gets the most out of their equipment:

- Installation Qualification

- Operational Qualification

- Performance Qualification

- Process Validation

- Training

AFTER-SALES 07

Upon completion of the project, our expert team will be available to assist with:

- Any technical advice or questions on FSSE® machinery or operations

- Maintenance services and revamping of installations carried out by FSSE® or other companies

- Repair service

- Spare parts service

Our after-sales process has been designed with each of our customers in mind, to provide ongoing support and ensure their satisfaction with FSSE® products and services.